Complete Range of Air Compressors

From 1 HP to 200+ HP, discover our comprehensive range of air compressors engineered for reliability, efficiency, and performance across all industrial applications.

SJBrand

Screw Air Compressors

High-efficiency rotary screw compressors for continuous industrial operations

Power Range

10-200 HP

Pressure Range

7-16 Bar

Key Applications

Continuous OperationIndustrial ManufacturingHigh CFM Requirements

SJBrand

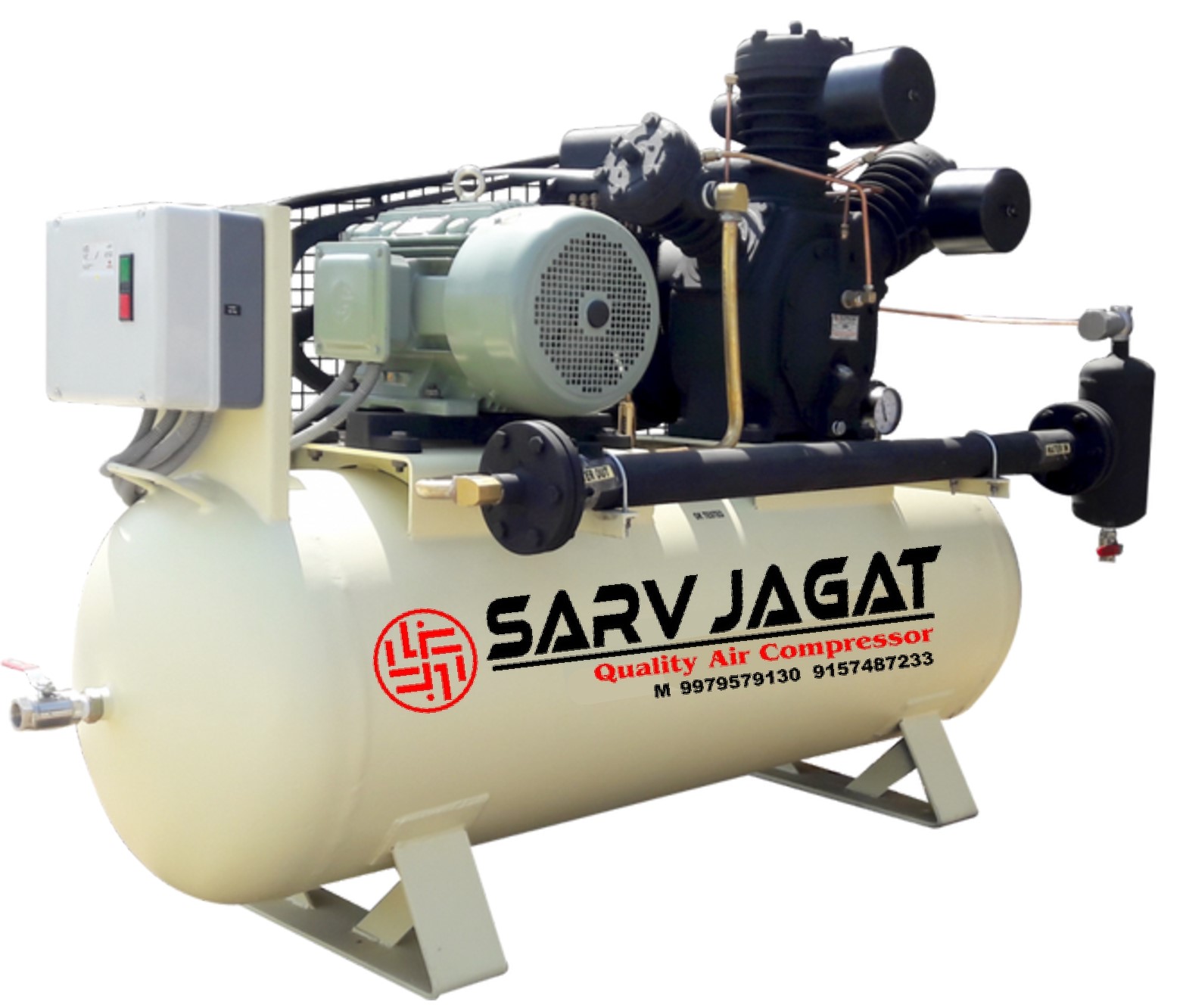

Reciprocating Piston Compressors

Robust piston compressors for heavy-duty and intermittent applications

Power Range

1-25 HP

Pressure Range

7-35 Bar

Key Applications

Heavy Duty OperationsHigh Pressure ApplicationsWorkshop Use

SJBrand

Specialized Compressors

Custom-engineered solutions for specific industrial requirements

Power Range

7.5-30 HP

Pressure Range

20-40 Bar

Key Applications

PET Bottle BlowingHigh Pressure SystemsVacuum Applications

SJBrand

Accessories & Components

Complete range of air treatment and storage accessories

Power Range

All Sizes

Pressure Range

Up to 16 Bar

Key Applications

Air TreatmentStorage SolutionsSystem Integration

Technical Specifications

Detailed technical specifications and performance parameters for our reciprocating air compressor range.

Performance Specifications

Key performance parameters and operating ranges

| Parameter | Range/Value | Unit |

|---|---|---|

| Working Pressure | 7 to 40 bar | bar |

| Free Air Delivery | 0.5 to 500 | m³/min |

| Motor Power | 3 to 500 | HP |

| Efficiency | Up to 95% | % |

| Noise Level | < 75 | dB(A) |

Certifications & Standards

ISO 9001:2015ISO 14001:2015OHSAS 18001:2007CE MarkingMSME CertificationAPI Standards

Compressor Technology Comparison

Compare different compressor technologies to find the best solution for your specific application requirements.

Reciprocating

Positive displacement compressors using pistons

Pressure:

7-40 bar

Capacity:

0.5-50 m³/min

Efficiency:

85-90%

Best For:

Small to medium applications

Key Advantages:

- ✓High pressure capability

- ✓Excellent for intermittent use

- ✓Lower initial cost

- ✓Simple maintenance

Applications:

Automotive serviceSmall workshopsPneumatic toolsPaint spraying

Rotary Screw

Continuous operation with twin rotating screws

Pressure:

5-13 bar

Capacity:

1-500 m³/min

Efficiency:

90-95%

Best For:

Continuous industrial use

Key Advantages:

- ✓Continuous duty cycle

- ✓Quiet operation

- ✓Compact design

- ✓Oil-free options available

Applications:

Manufacturing plantsFood processingPharmaceuticalElectronics

Centrifugal

Dynamic compressor using rotating impellers

Pressure:

1-8 bar

Capacity:

50-5000 m³/min

Efficiency:

80-85%

Best For:

High volume applications

Key Advantages:

- ✓Very high capacity

- ✓Oil-free air

- ✓Low maintenance

- ✓Smooth operation

Applications:

Large industrial plantsPower generationChemical processingSteel production

Feature Comparison Matrix

Side-by-side comparison of key features across compressor types

| Feature | Reciprocating | Rotary Screw | Centrifugal |

|---|---|---|---|

| Initial Cost | Low | Medium | High |

| Operating Cost | Medium | Low | Low |

| Maintenance | High | Medium | Low |

| Noise Level | High | Low | Medium |

| Duty Cycle | Intermittent | Continuous | Continuous |

| Pressure Range | High | Medium | Low |

Need Help Choosing the Right Compressor?

Our technical experts can help you select the optimal compressor technology based on your specific requirements, operating conditions, and budget.